Methods for Attaching Corrugated Metal to Cabinet Doors: How To Attach Corrugated Metal To Cabinet Doors

Attaching corrugated metal to cabinet doors offers a unique aesthetic, adding a rustic or industrial touch to your kitchen or other spaces. However, the method you choose will significantly impact the final look and durability of your project. Careful consideration of the materials and techniques is crucial for a successful outcome.

Methods of Attachment

Three primary methods exist for securely attaching corrugated metal to cabinet doors: using rivets, employing construction adhesive, and utilizing screws. Each method presents a unique set of advantages and disadvantages depending on your skill level, the type of metal, and the desired aesthetic.

| Method | Tools | Materials | Advantages/Disadvantages |

|---|---|---|---|

| Riveting | Riveting gun, rivet setter, drill with metal bit, safety glasses | Corrugated metal, rivets (appropriate size and material), cabinet door | Advantages: Strong, durable bond; relatively quick; clean look. Disadvantages: Requires specialized tools; potential for damage if not done carefully; not easily reversible. |

| Construction Adhesive | Caulk gun, measuring tape, putty knife | Corrugated metal, high-strength construction adhesive, cabinet door | Advantages: Simple application; no visible fasteners; suitable for lighter weight metal. Disadvantages: Requires precise application; curing time; bond strength may be less than other methods; not ideal for areas with high stress or moisture. |

| Screws | Drill with appropriate drill bit, screwdriver, countersink bit (optional), measuring tape | Corrugated metal, screws (appropriate size and material), cabinet door, wood filler (optional) | Advantages: Relatively easy; readily reversible; strong bond with proper screw selection. Disadvantages: Visible screw heads; potential for cracking the metal or wood if not drilled carefully; requires careful screw placement to avoid damage. |

Cabinet Door and Corrugated Metal Preparation

Before beginning the attachment process, thorough preparation of both the cabinet door and the corrugated metal is essential for a secure and lasting bond. This involves cleaning, sanding, and potentially applying a primer or other protective coatings. Cleaning removes any dirt, grease, or old finish that could interfere with adhesion. Sanding helps to create a better surface for the adhesive or fasteners to grip. Pre-treatments like a rust inhibitor for the metal or a wood conditioner for the cabinet door can further enhance the longevity of the project.

Step-by-Step Instructions: Using Screws

This method offers a balance between ease of use and strength, making it suitable for many projects. Remember to always wear appropriate safety gear, including safety glasses and gloves.

- Measure and Cut: Accurately measure the cabinet door to determine the necessary size of the corrugated metal. Add a small margin for error. Use metal shears or a cutting wheel to carefully cut the metal to size. Remember to consider any desired overhang or edge treatment.

- Pre-Drill Holes: Pre-drilling pilot holes in both the metal and the cabinet door is crucial to prevent cracking or splitting. Use a drill bit slightly smaller than the screw diameter.

- Position and Secure: Carefully position the corrugated metal on the cabinet door, ensuring it’s level and aligned. Use clamps to hold it in place while you begin screwing.

- Attach with Screws: Drive the screws through the pre-drilled holes, ensuring they are evenly spaced and securely fastened. Avoid over-tightening to prevent damage.

- Fill and Finish (Optional): If desired, fill the screw holes with wood filler, sand smooth, and apply a finishing coat to match the cabinet door and metal.

Considerations for Material Selection and Design

Choosing the right corrugated metal and designing its application on cabinet doors requires careful consideration of aesthetics, durability, and practicality. The material’s gauge, composition, and finish will significantly impact the final look and longevity of your project. Furthermore, the chosen fastening method will influence both the visual appeal and the structural integrity of the finished cabinet doors.

Corrugated Metal Types and Suitability

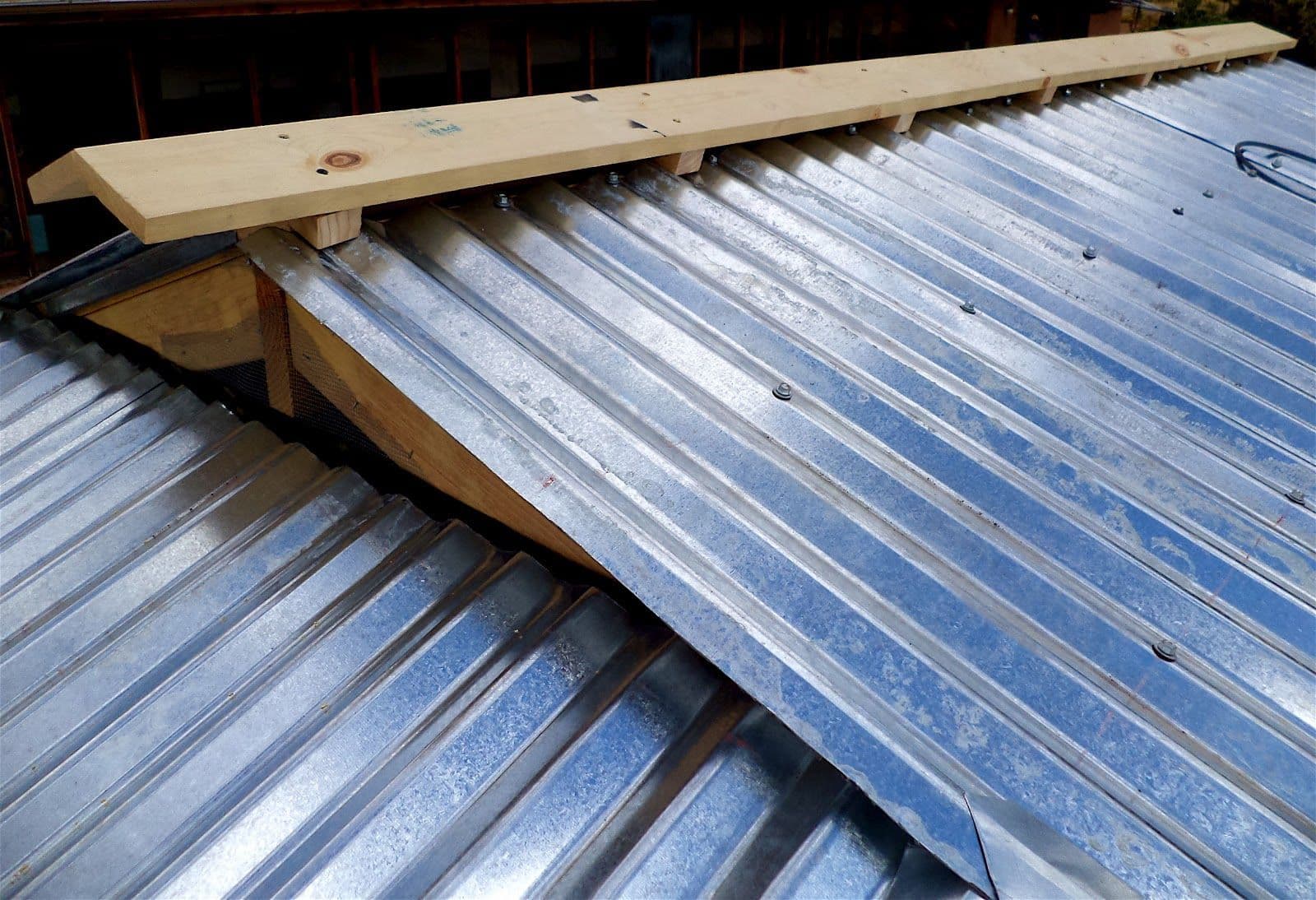

Several types of corrugated metal are suitable for cabinet doors, each with its own advantages and disadvantages. Galvanized steel is a common and cost-effective choice, offering good durability and resistance to rust. Aluminum offers a lighter weight option with excellent corrosion resistance, making it ideal for outdoor or humid environments. Stainless steel provides superior durability and resistance to corrosion, but it comes at a higher cost. The gauge of the metal (thickness) will influence its strength and rigidity; a heavier gauge will be more durable but also more difficult to work with. Finally, the finish can range from a simple, uncoated surface to powder-coated options offering a wide variety of colors and textures. Consider the overall style of your kitchen and the level of durability needed when making your selection. For example, a high-traffic kitchen might benefit from the added strength of stainless steel, while a more rustic design might be well-served by galvanized steel with a weathered finish.

Aesthetic Design Styles

Three distinct aesthetic styles can be achieved by incorporating corrugated metal into cabinet door designs:

- Industrial Chic: This style uses the corrugated metal as a prominent feature, often leaving the metal’s raw texture visible. The metal could be applied to the entire door face, or used as a frame or inlay, creating a visually striking contrast with the cabinet’s wood or other materials. The overall effect is a bold, modern, and slightly rugged look. Imagine a dark grey corrugated metal panel framed by lighter wood, giving a sense of urban sophistication.

- Rustic Farmhouse: This style utilizes a more subtle application of corrugated metal, perhaps using a thinner gauge and a weathered or painted finish. The metal could be incorporated as a decorative accent, such as a thin strip along the edge of the door, or as a small panel inset into a larger wood surface. The overall feel is warm, inviting, and slightly vintage. Picture a light-colored wood door with a narrow band of aged, copper-colored corrugated metal along its edges, adding a touch of character.

- Modern Minimalist: This style emphasizes clean lines and simplicity. The corrugated metal is used sparingly and strategically, perhaps as a single, geometric panel on a plain, solid-colored cabinet door. The metal’s texture might be minimized through a smooth paint finish. The overall impression is one of understated elegance and sophistication. Envision a sleek white cabinet door with a single, rectangular panel of brushed stainless steel, creating a subtle but effective visual focal point.

Fastener Comparison

The choice of fasteners significantly impacts both the visual appeal and structural integrity of the finished product. Here’s a comparison of common fastening methods:

- Screws: Screws offer good holding power and are relatively easy to install. However, the screw heads can be visible, potentially detracting from the aesthetic appeal depending on the screw type and finish. Countersinking the screws can help to minimize their visibility.

- Rivets: Rivets provide a strong and permanent bond, and their heads can be aesthetically pleasing, particularly in industrial-style designs. However, they require specialized tools for installation, making them less convenient for DIY projects.

- Adhesives: Adhesives offer a clean and seamless look, concealing the fastening method entirely. However, they may not be as strong or durable as screws or rivets, particularly for larger or heavier metal panels. Choosing a high-quality adhesive designed for metal-to-wood bonding is crucial for success.

Addressing Potential Challenges and Troubleshooting

Attaching corrugated metal to cabinet doors, while offering a unique aesthetic, presents several potential hurdles. Careful planning and execution are key to achieving a professional-looking and durable finish. Understanding common challenges and implementing preventative measures will significantly improve the outcome of your project.

Potential Challenges During Attachment

Uneven surfaces, metal warping, and fastener failure represent three significant challenges encountered when attaching corrugated metal to cabinet doors. Addressing these issues proactively minimizes frustration and ensures a successful project.

- Uneven Surfaces: Cabinet doors are rarely perfectly flat. Significant inconsistencies can lead to difficulty in achieving a flush fit with the corrugated metal. To mitigate this, use a thin layer of adhesive caulk or construction adhesive along the back of the metal sheet before applying it to the door. This will help fill small gaps and provide a more even surface. For larger discrepancies, consider using shims to level the metal before securing it. Precise measurement and marking are also crucial before attaching the metal.

- Metal Warping: Corrugated metal, particularly thinner gauges, is susceptible to warping during handling and attachment. This can result in an uneven final product. To prevent warping, handle the metal carefully, avoiding excessive bending or pressure. Use an appropriate number of fasteners spaced evenly to distribute pressure. Pre-drilling pilot holes is strongly recommended to prevent the metal from tearing or buckling during screw insertion. Choosing a thicker gauge of metal will also improve its resistance to warping.

- Fastener Failure: Using inappropriate fasteners or improper installation techniques can lead to fastener failure. This can range from stripped screw holes to fasteners pulling through the metal or the cabinet door. To prevent this, select fasteners appropriate for both the metal and the cabinet door material. Pre-drilling pilot holes is crucial to prevent stripping. Consider using self-tapping screws designed for metal, ensuring they are long enough to provide sufficient grip. Using too few fasteners or spacing them unevenly can also lead to failure, so maintain even spacing and sufficient fastener quantity.

Troubleshooting Guide

Addressing common problems encountered during the process requires a systematic approach. This troubleshooting guide helps identify and resolve issues effectively.

- Problem: Corrugated metal is unevenly attached. Solution: Carefully remove the metal sheet, apply adhesive caulk or shims to level the surface, and reattach the metal. Ensure even pressure distribution during reattachment.

- Problem: Fasteners are pulling through the metal. Solution: Use longer fasteners or switch to a stronger fastener type. Pre-drilling pilot holes is highly recommended to prevent this.

- Problem: Metal is warped after attachment. Solution: This is difficult to rectify after the fact. Careful handling and pre-drilling are preventative measures. In some cases, gentle manipulation and re-fastening may help, but this may not always restore a perfect finish.

- Problem: Screw holes are stripped. Solution: Use wood filler or epoxy to fill the stripped holes, allowing it to cure completely. Then re-drill pilot holes and use new fasteners.

Preventative Measures, How to attach corrugated metal to cabinet doors

Proactive steps significantly reduce the likelihood of encountering problems during the attachment process. Implementing these preventative measures ensures a smoother and more successful project.

- Proper Material Selection: Choose a gauge of corrugated metal appropriate for the application. Thicker gauges are less prone to warping. Select fasteners specifically designed for metal and the cabinet door material. Consider the overall weight of the metal sheet to ensure adequate support from the cabinet door structure.

- Thorough Surface Preparation: Ensure the cabinet door surface is clean, dry, and free from any debris. Addressing any significant surface imperfections before attaching the metal sheet is crucial. This may involve sanding or filling in gaps.

- Precise Measurement and Marking: Accurate measurements and marking are essential for a neat and even fit. Take your time to ensure the metal sheet is correctly positioned before attaching it. Using a template can greatly improve accuracy.

- Pre-Drilling Pilot Holes: Always pre-drill pilot holes before inserting screws, especially when working with metal. This prevents the metal from tearing or buckling and ensures a more secure fastening.

- Even Fastener Distribution: Use an appropriate number of fasteners, evenly spaced to distribute the pressure across the entire metal sheet. Avoid concentrating fasteners in one area, which can lead to warping or fastener failure.